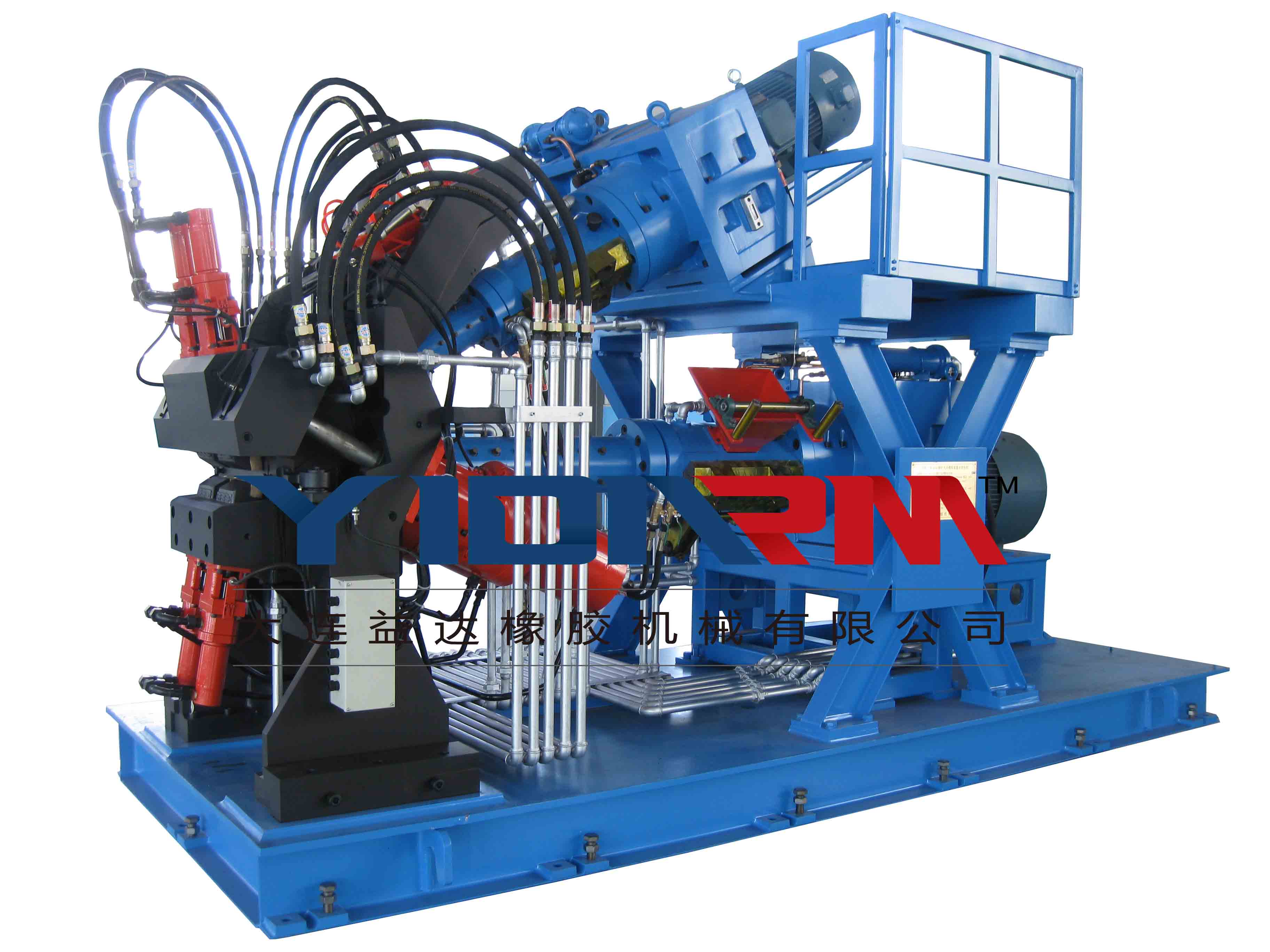

Pin-barrel cold feed rubber extruderModel:

Feature:The machine is used for extrusion of various rubber products and rubber feeding.

Structural features:

1.Pin-barrel cold feed rubber extruders are made by the company with introduced technologies. Different extrusion heads are applied to extrude various half-finished rubber products. The machines can also be used to feed rubber to manglers.

2.The barrel is composed of several zones. In the feeding zone, the spiral slots work with the side rolls to enhance feeding capability .In the plasticizing and extrusion zones, different numbers of pins are fitted.

3. The screw is processed and polished with the foreign-made milling machine and is featured by excellent geometric precision. Nitrogenation treatment makes it more wear-resistant.

4.The gears in the reducer are made of alloyed steel, and their teeth are hard.

5.A hot water circulation device automatically controls temperature in each zone.

6.The machine is driven by a DC motor and AC motor.

|

Dalian Yida Rubber Machinery Co.,Ltd

Introduction

Full Text

Main Products

-

Hot feed rubber extruderModel:

Feature:The machine is equipped with inner tube and tire tread extrusion heads and can also be equipped with other extrusion heads as required by users. 2.Temperature measuring and indicating device install in the machine body. The feeding zone over 150 is equipped with side rolls for the enhancement of feeding capability. The screws and bushes are subjected to nitrogenation treatment to get enough strength and wear-resistance. 4.The reducer has a forced lubrication unit, which is featured by high transmission efficiency, long service life and low noise. The machine over 150 is driven by a variable-open type for easy rubber removal. -

Compound tire tread extruder setsModel:

Feature:1.The machine adopts compound technology to make the tire tread precise size and compact structure. 2.The series machines adopt introduced technologies and equipments and select the domestic ancillaries and some imported ancillaries. 3.The set is supplied in two types, dual cooling and one-cooling-one heating. It’s also equipped with a reducer with hard-tooth gears, an automatically hydraulic tread head and a temperature/ pressure measuring device. 4. The temperature of each part is controlled sectionally by intelligent temperature control device. 5. The machine adopts DC and AC motor drive.